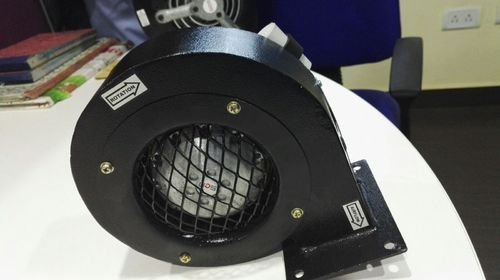

Forced Cooling Blower Supplier

We are known as the top Forced cooling blower supplier, manufacturer and exporter in India. We offer wide range of cooling blowers to fulfill your all applications. A forced cooling blower, also known simply as a cooling blower or a forced air cooling system, is a device used to provide active cooling to various systems or components by circulating air. It typically consists of a motorized fan enclosed within a housing, with the capability to move air at a controlled rate.

Applications

Forced cooling blowers are commonly employed in electronic devices, machinery, industrial equipment, and even in automotive applications where efficient cooling is necessary to maintain optimal operating temperatures and prevent overheating. They are particularly useful in dissipating heat generated by electronic components such as processors, power supplies, or other heat-producing elements.

The operation of a forced cooling blower involves drawing air from the surroundings and directing it over the surface of the component or system to be cooled. As the air flows over the hot components, it absorbs heat and carries it away, helping to maintain safe operating temperatures.

Product Description

- THIS PRODUCT USED IN PHARMA MACHINERY, PLASTIC MACHINERY, PRINTING MACHINERY.

- FOR THIS WE HAVE MANY MODELS SERIES ARE 9EC, 10EC

- SINGLE PHASE AND THREE PHASE BOTH ARE AVAILABLE

How Forced Cooling Blower Works?

A forced cooling blower works by using a motorized fan to circulate air over a hot surface or component, thereby dissipating heat and cooling the object. Here’s a more detailed breakdown of how it typically operates:

Motorized Fan: At the heart of the forced cooling blower is a motorized fan. This fan is usually driven by an electric motor and is responsible for generating airflow.

Enclosure or Housing: The fan is typically housed within an enclosure or housing, which helps to direct and focus the airflow. The housing may have openings or ducts to control the direction of the airflow and to ensure that it effectively reaches the target area requiring cooling.

Air Intake: The blower draws in ambient air from its surroundings through an intake port or opening. This air is typically cooler than the hot surface or component that needs to be cooled.

Airflow Direction: The fan inside the blower pushes the incoming air through the enclosure and directs it towards the hot surface or component. The airflow is directed in such a way that it maximizes contact with the hot area, facilitating efficient heat transfer.

Heat Transfer: As the air flows over the hot surface, it absorbs heat from the component. This process is facilitated by convection, where the air molecules in contact with the hot surface gain energy and rise, allowing cooler air to take their place. The continual circulation of air helps to maintain a temperature gradient, allowing heat to be continuously transferred away from the hot surface.

Exhaust: Once the air has absorbed heat from the hot surface, it exits the enclosure through exhaust ports or openings. This exhaust air is typically warmer than the intake air, having absorbed heat from the hot surface.

Cooling Effect: By continuously circulating air over the hot surface, the forced cooling blower helps to dissipate heat, preventing the surface from reaching excessively high temperatures. This helps to maintain optimal operating conditions for the component or system, improving reliability and performance.

Overall, the forced cooling blower operates on the principle of using airflow to facilitate heat transfer, thereby cooling hot surfaces or components and maintaining stable operating temperatures.

Benefit of Forced Cooling Blower

Forced cooling blowers offer several benefits across various applications where efficient heat dissipation is necessary. Some of the key benefits include:

Prevents Overheating: The primary benefit of forced cooling blowers is their ability to prevent overheating of components or systems. By continuously circulating air over hot surfaces, they help dissipate heat effectively, ensuring that temperatures remain within safe operating limits.

Enhances Component Lifespan: Overheating can significantly reduce the lifespan of electronic components, machinery, and other equipment. By keeping temperatures in check, forced cooling blowers help to extend the lifespan of these components, reducing the risk of premature failure and the need for costly repairs or replacements.

Maintains Performance: Many devices and systems are designed to operate optimally within a specific temperature range. When temperatures rise too high, performance can suffer. Forced cooling blowers help maintain consistent temperatures, ensuring that equipment performs reliably and efficiently.

Increases Efficiency: In electronic devices such as computers, servers, and power supplies, excessive heat can decrease efficiency and performance. By cooling these components, forced cooling blowers can help maintain energy efficiency and optimize performance.

Compact Design: Forced cooling blowers typically have a compact design, making them suitable for use in applications where space is limited. They can be integrated into various systems without requiring significant modifications or additional space.

Versatility: Forced cooling blowers can be used in a wide range of applications across industries such as electronics, automotive, manufacturing, and HVAC (heating, ventilation, and air conditioning). They can be tailored to specific cooling requirements, offering versatility in design and functionality.

Cost-Effectiveness: Implementing forced cooling blowers can be a cost-effective solution compared to alternative cooling methods such as liquid cooling systems or passive heat sinks. They often require less maintenance and are relatively simple to install and operate.

Adaptability: Forced cooling blowers can be designed with adjustable speed settings or directional control, allowing for customization to suit the specific cooling needs of different applications. This adaptability makes them versatile and effective in diverse environments.

Overall, forced cooling blowers play a critical role in maintaining optimal operating conditions, improving reliability, and extending the lifespan of components and systems across various industries.

Contact Forced Cooling Blower Supplier

Forced cooling blowers can vary in size, design, and capacity depending on the specific cooling requirements of the application. They may feature adjustable speed settings, directional control, and other customizable features to optimize cooling performance. Additionally, they can be integrated into larger cooling systems or used as standalone units depending on the needs of the application.These blowers are available in market leading prices.